Making Your Story

– A Success Story

Our Areas of Service | Scope of our Supply

Food

Animal food

Baby food

Baking (bread & flour)

Beverages (coffee, tea & herbal)

Biscuits

Cereal products

Confectionery (chocolate & sweets)

Dairy products

Dressing

Dried fruits

Pasta products

Preserved goods

Primary ingredients (sugar & salt)

Sauces

Soups

Spices & Flavorings

Pharma

APIs

Tablets

Capsules

Vitamins & Supplements

Herbs

Cosmetics (Gel, Lotions, Cream…)

Animal Drugs

Tobacco

Chemical

Cleaning Agents (Detergents)

Compounding (Granulation)

Construction Chemicals (Seal, Glue, Insulation Materials…)

Fiber

Key Chemicals

Mineral & Metal Powder

Paper Industry

Paints & Lacquers

Personal Care (Toothpaste, Shampoo…)

Petrochemicals

PE Wax

Pigments

Plastic Processing

Powder Coating

Protective Agents (Plasticizers, frightening Agents…)

PVC-Dry blend (Cables…)

Toners

Waste Reduction

Automotive

Cable

Plastics

CASE STUDY - FOOD

CASE STUDY - PHARMA

CASE STUDY - CHEMICAL

OUR EXPERTISE

CASE STUDY - FOOD

Cocoa Processing

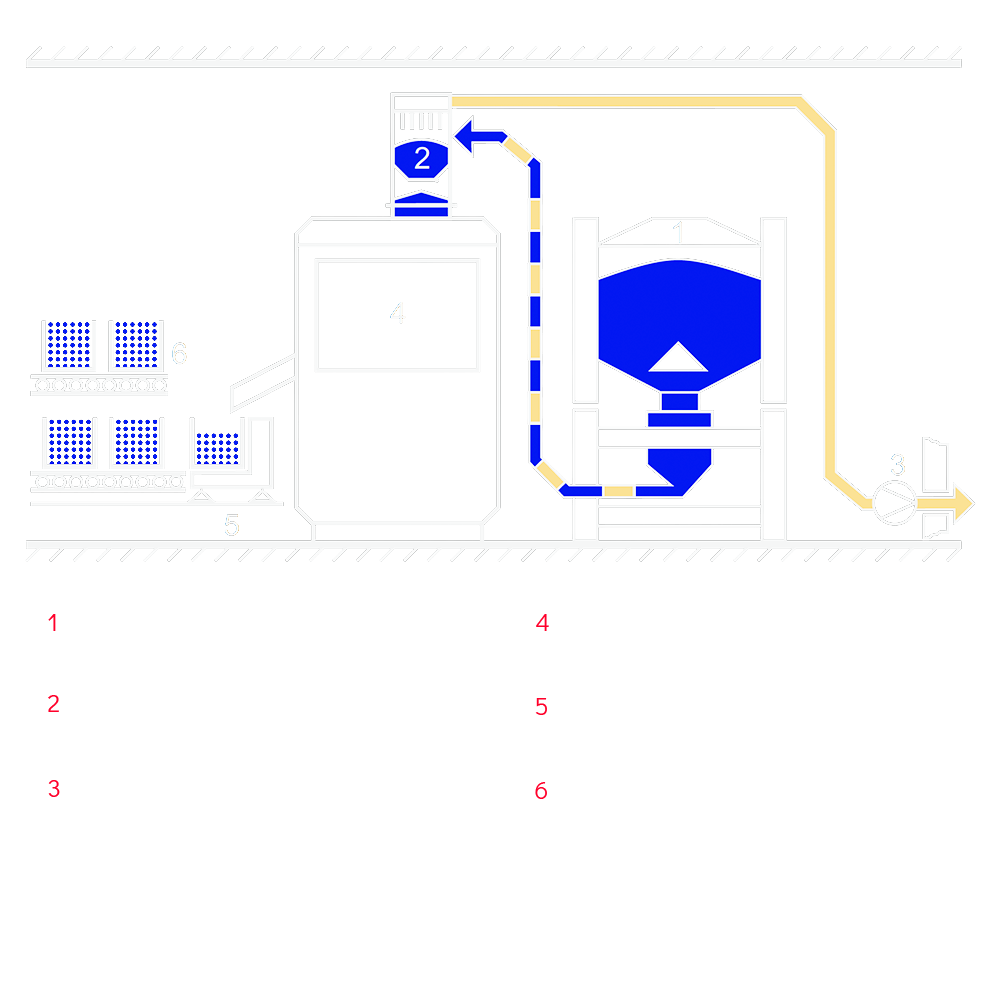

We have greatly improved the efficiency of cocoa production [Cleaning, Breaking cocoa shells → Sterilizing & Alkalization→ Roasting→ Nib Grinding→ Pressing→ Cocoa cake grinding]. The old cocoa cake grinding system required additional tube coolers, there were risks of pin breakage from wear and it required more heat input and higher air flow.

With the improvements in processing – the benefits now include: low specific energy requirement, compact/space-saving design, simple to clean, low noise emission, pressure-shock resistant and wear-protected.

Cocoa Press Cake Grinding Process

CASE STUDY - PHARMA

CASE STUDY – PHARMACEUTICAL

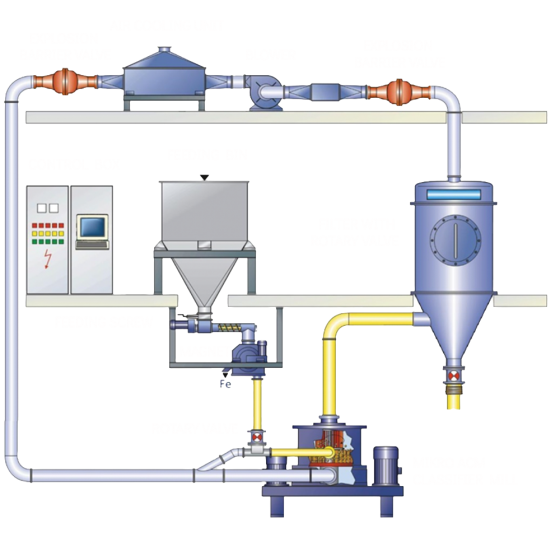

Automatic Feeding Systems

The world’s leading supplier of dialysis products for chronic kidney failure has adopted our automatic feeding system for batching lines. This has resulted in the rapid execution of qualification and validation measures, high dosing accuracies [weighing and deposition of ingredients], the expansion of existing batch lines – including new production capacities, and exceptional cross contamination avoidance.

The finding was an efficient multi-product line for varying batch sizes.

CASE STUDY - CHEMICAL

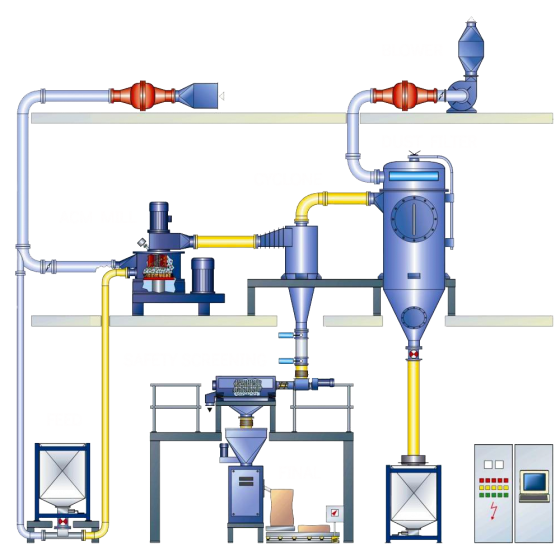

Production of Powder Coatings

We see general trends of cost reduction, higher safety and responsible waste reduction. We are integrated at every level of production – for every process [Raw materials → Pre-mixing→ Extruding→ Cooling and Pre-grinding→ Fine grinding→ Sieving & Packing].

Every feature is user-friendly and built to ensure: easy cleaning [non-stick coating] – deposit reduction, and easy recycling – with the grinding-classifying system, fines are automatically recycled to the extruder.

Grinding-classifying system for powder paint

OUR EXPERTISE

Powder Processing

- Granulators and Shredders

- Table Voller Mills

- Ball Mills and Agitated Media Mills

- Fine Impact Mills and Classifier Mills

- Jet Mills

- Classifier and Air Classifiers:

- Compactors and Roller Presses

- Particle design & Nano technology

- Isolators/Containment

- Flake Crushers, Bexmills, Pre-crusher and Hammer Mills

- Pelleting Machines, Basket Extruders and Spheronizer

Mixer Technology for Chemicals

- Container mixer C technology PRO

- Vertical high speed mixer type M

- Vertical universal mixer type UT uni- tec

- Horizontal cooling mixer type K

- Horizontal universal mixer type H

- Heating / cooling mixer combination type M/K – Flex-line

- Heating / cooling mixer combination type M/K – Eco-line

- Laboratory mixer type M

Advanced Material Handling

- Batch and minor quantity automation: Mixer feeding

- Advanced mixing, dispersing and homogenizing

- Discharge systems

- Filling systems

- Container systems

- Highly accurate dosing of powder into liquids

- Dosing systems

- Manufacturing Execution System (MES)

- Plant controls

- Pneumatic conveying systems (for granular, powdered and lumpy bulk materials)

- Process control system

- Product feeding systems (for sacks, big bags, drums and containers)

- Screening systems (preserve the quality of bulk solids and liquids)

- Silo and discharge systems

- Vacuum weighing systems (for large and medium-sized components)

Mixer Technology for Food and Pharmaceuticals

- Vertical single-shaft mixer

- Vertical twin-shaft mixer

- Conical mixer

- Vacuum dryer / mixer dryer

- Conical dryer reactor

- Single shaft mixer with standard drum

- Granulator continuous

- Container mixer

- Continuous mixer

- Powder mixer KS I

- Industrial mixer KS II